Press Releases

National Gypsum Donates $1 Million to Advance STEM Education

As part of our commitment to Building Products for a Better Futur...

Read More

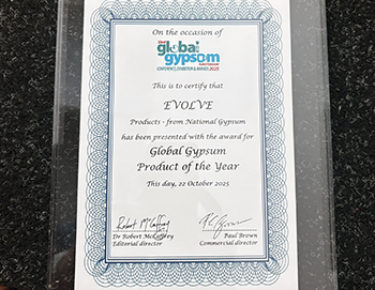

EVOLVE Product Line Wins Global Gypsum Product of the Year

Award underscores National Gypsum’s commitment to lightweight des...

Read More

Introducing the EVOLVE™ Family of Products

The latest innovation from National Gypsum will transform gypsum ...

Read More

Introducing National Gypsum’s Fire & Sound Assembly Selector™

New interactive tool enhances project planning and estimating

Read More

National Gypsum Donates $1 Million to Advance STEAM Education

As part of our commitment to Building Products for a Better Futur...

Read More

Lori Hudson Appointed to Local Federal Reserve Board in Charlotte

Hudson will serve as a director on the board of the Federal Reser...

Read MoreMedia Contact

Beth Straeten

704-816-0294 | 704-365-7327 | beths@nationalgypsum.com

NGConnects

What is NGConnects?

Safeguarding shafts with impact-resistant drywall

High-rise safety relies on code-compliant shaft enclosures and AS...

Read More

Safeguarding stair and elevator shafts with impact-resistant drywall

High-rise safety relies on code-compliant shaft enclosures and AS...

Read More

Episode 9: Why use hard roof coverboards?

Learn the science behind hard roof coverboards and the benefits o...

Read More

Designing wind-resistant structures: Sheathing and roof board considerations

eXP Sheathing and DEXcell Roof Board products help resist damage ...

Read More

Designing wind-resistant structures: Sheathing and roof board considerations

eXP Sheathing and DEXcell Roof Board products help resist damage ...

Read More

Simplifying area separation wall challenges

Best practices for solving area separation wall design challenges...

Read MoreCommunity Impact

Community Impact

Military Veteran Associates Featured in Case Study with the Manufacturing Institute

Read More

Community Impact

National Gypsum Company Sponsors ‘Cool Globes’ Exhibit in Charlotte

Read More

Community Impact

Marketing And Sales Partner With Habitat for Humanity Central Arizona

Read More

Community Impact

Veterans Day: A Way To Honor Those Who Served

Read More

Community Impact

Customer Service Center Anniversary Celebration

Read More

Community Impact

Company Kicks Off United Way Campaign

Read MoreIn the News

See All

Business NC Spotlights National Gypsum’s Quiet Strength

Story highlights the values, leadership and steady approach that ...

Read More

Walls & Ceilings Highlights ProForm Resources

Resources help users select which of the five levels of finish fo...

Read More

AWCI features National Gypsum's Fire & Sound Assembly Selector

New tool allows users to save valuable time and enhance project e...

Read More

If Walls Could Talk: National Gypsum Milestones and Innovations

Chris Whitmire joined Wall & Ceilings "If Walls Could Talk" podca...

Read More

Walls & Ceilings highlights National Gypsum's Centennial

National Gypsum Company celebrates its 100th Anniversary

Read More

Metro Interiors highlights heavy duty board options from Gold Bond

Chris Whitmire, Director of Product Marketing discusses the diffe...

Read MoreWant to stay up-to-date? Join Our Newsletter